Current location:

Links:

-

In conclusion, the rotary jackhammer, with its potent blend of power, versatility, and functionality, has carved a niche for itself in the realm of heavy machinery. It's a testament to human innovation and our relentless pursuit of efficiency in construction and demolition tasks. Despite the advent of new technologies, the rotary jackhammer remains an irreplaceable tool, a true workhorse in the dynamic world of construction.

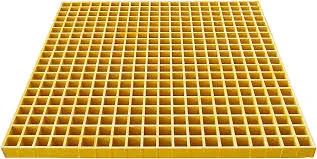

- Corrosion Resistant: FRP molded grating has good corrosion resistance, does not rust, and has a long service life, which reduces the cost of use, including life cost and maintenance cost. In conclusion, fiberglass covers represent a pinnacle of functionality and form. Whether safeguarding leisure or industrial assets, enhancing architectural aesthetics, or providing practical solutions to everyday challenges, these covers embody the transformative power of fiberglass. As technology continues to advance, the applications for fiberglass covers will likely expand, further cementing their status as a vital component across diverse fields. In the vast universe of technology, it is often the smallest components that make the biggest difference. One such seemingly insignificant yet pivotal piece is the button bit, an innovation that has revolutionized user interaction with machines and devices. This article delves into the world of button bits, exploring their functionality, impact, and future prospects. Fiberglass Ladders A Versatile and Essential Tool In addition to their robustness, FRP pipes also contribute to environmental sustainability The Pioneering Role of Gasoline-Powered Rock Drills in Mining and Construction Ingersoll Rand, an American company, is celebrated for its air compressor technology that powers many of their rock drills. Their products are known for their robustness and ability to perform in harsh environments. Their focus on ergonomics and operator safety has set new standards in the industry. Hex shank drill bits are available in a wide range of sizes and materials, catering to various drilling needs. From steel and masonry to wood and plastic, there's a hex shank drill bit suitable for each material. They are commonly made from high-speed steel (HSS) or carbide, both renowned for their resilience and ability to maintain sharpness even after extended use They are commonly made from high-speed steel (HSS) or carbide, both renowned for their resilience and ability to maintain sharpness even after extended use

- shipping centers One of the most significant advancements in rock drilling technology was the introduction of the pneumatic drill in the early 20th century. This drill used compressed air to rotate a bit, which significantly increased drilling speed and efficiency. However, it still required a great deal of physical effort and was limited in its application due to its size and weight. In addition to their power, air jack hammers are also highly durable and long-lasting. These tools are built to withstand the rigors of tough construction and demolition work, so you can rely on them to perform consistently day in and day out. With proper maintenance and care, an air jack hammer can last for many years, making it a solid investment for any contractor or construction professional. In terms of performance, this jack hammer would boast a higher output than traditional models. It would deliver more blows per minute with increased force, making short work of even the toughest materials. For instance, where a standard jack hammer might struggle to penetrate solid rock, the Extreme Jack Hammer would effortlessly cleave through it, thanks to its advanced impact mechanics.

Fiberglass, or glass-reinforced plastic (GRP), is a composite material made by combining glass fibers with a polymer resin matrix. This composition imparts exceptional strength and resilience to the tanks, making them resistant to corrosion, weathering, and impact. Unlike traditional metal or concrete tanks, fiberglass tanks do not rust, crack, or leach harmful chemicals, ensuring the safety and integrity of the stored substances. The drill motor, or hammer, is the powerhouse of the rock drill. It generates the force needed to drive the bit into the rock. In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency

In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency rock drill parts. The Pivotal Role of Fiberglass Pipe Fittings in Modern Infrastructure In conclusion, hardened drill bits are an essential tool for anyone involved in construction or engineering work. Their ability to maintain their sharpness and cutting efficiency under heavy loads and repetitive use, as well as their versatility in drilling through a wide range of materials, make them an invaluable asset in any workshop or job site. So if you're in the market for a new set of drill bits, be sure to consider investing in a high-quality set of hardened drill bits from a reputable brand like Dewalt. In conclusion, the price increase of the Jack Hammer can be attributed to a combination of factors, including increased demand, rising raw material costs, transportation expenses, and supply chain disruptions. While these factors may be temporary, they have had a significant impact on the price of this popular power tool. Consumers may need to consider alternative options or wait for prices to stabilize before making a purchase.

rock drill parts. The Pivotal Role of Fiberglass Pipe Fittings in Modern Infrastructure In conclusion, hardened drill bits are an essential tool for anyone involved in construction or engineering work. Their ability to maintain their sharpness and cutting efficiency under heavy loads and repetitive use, as well as their versatility in drilling through a wide range of materials, make them an invaluable asset in any workshop or job site. So if you're in the market for a new set of drill bits, be sure to consider investing in a high-quality set of hardened drill bits from a reputable brand like Dewalt. In conclusion, the price increase of the Jack Hammer can be attributed to a combination of factors, including increased demand, rising raw material costs, transportation expenses, and supply chain disruptions. While these factors may be temporary, they have had a significant impact on the price of this popular power tool. Consumers may need to consider alternative options or wait for prices to stabilize before making a purchase.

Another key advantage of fiberglass is its resistance to corrosion In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency

In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency rock drill parts. The Pivotal Role of Fiberglass Pipe Fittings in Modern Infrastructure In conclusion, hardened drill bits are an essential tool for anyone involved in construction or engineering work. Their ability to maintain their sharpness and cutting efficiency under heavy loads and repetitive use, as well as their versatility in drilling through a wide range of materials, make them an invaluable asset in any workshop or job site. So if you're in the market for a new set of drill bits, be sure to consider investing in a high-quality set of hardened drill bits from a reputable brand like Dewalt. In conclusion, the price increase of the Jack Hammer can be attributed to a combination of factors, including increased demand, rising raw material costs, transportation expenses, and supply chain disruptions. While these factors may be temporary, they have had a significant impact on the price of this popular power tool. Consumers may need to consider alternative options or wait for prices to stabilize before making a purchase.

rock drill parts. The Pivotal Role of Fiberglass Pipe Fittings in Modern Infrastructure In conclusion, hardened drill bits are an essential tool for anyone involved in construction or engineering work. Their ability to maintain their sharpness and cutting efficiency under heavy loads and repetitive use, as well as their versatility in drilling through a wide range of materials, make them an invaluable asset in any workshop or job site. So if you're in the market for a new set of drill bits, be sure to consider investing in a high-quality set of hardened drill bits from a reputable brand like Dewalt. In conclusion, the price increase of the Jack Hammer can be attributed to a combination of factors, including increased demand, rising raw material costs, transportation expenses, and supply chain disruptions. While these factors may be temporary, they have had a significant impact on the price of this popular power tool. Consumers may need to consider alternative options or wait for prices to stabilize before making a purchase.  Another significant benefit is their lightweight nature. Plastic gratings weigh significantly less than their metal counterparts, which not only simplifies transportation and handling but also reduces the structural requirements for installation. This translates to lower overall costs and easier maintenance, as they can be easily replaced or repaired without heavy lifting equipment.

Another significant benefit is their lightweight nature. Plastic gratings weigh significantly less than their metal counterparts, which not only simplifies transportation and handling but also reduces the structural requirements for installation. This translates to lower overall costs and easier maintenance, as they can be easily replaced or repaired without heavy lifting equipment. Weighing about 2.5 lbs square foot - about the same as 1/4-inch think flat sheet fiberglass plate, the grating over the flume is cut into sections so that it can be easily removed. Handholds are then either cut into each section or a bar of the grating is removed at one end of a grating section to allow an operator's gloved hand to lift the grating section out of the way.

To achieve optimal speed and efficiency in drilling operations, several strategies can be employed. One approach is to utilize advanced drilling technologies, such as downhole motors and mud pulse telemetry systems, which can improve penetration rates and provide real-time data on drilling conditions. Another strategy is to optimize drilling fluid formulations to reduce friction and improve borehole stability, thereby increasing drilling speed and reducing the risk of drill string failures. In conclusion, carbide conical buttons bits are more than just tools; they are key drivers of efficiency and productivity in rock drilling operations. Their durability, combined with advanced engineering, has made them a preferred choice among professionals worldwide. As technology continues to evolve, we can expect further advancements in carbide button bit design, further enhancing their performance and durability in the demanding world of rock drilling. The 20th century witnessed the advent of electric and hydraulic coal-cutting machines. These powerful tools could cut through coal seams with precision and speed, further minimizing manual labor and boosting productivity. Electric drills and saws also became essential for creating openings and driving tunnels deep into coal measures, making mining operations more extensive and efficient than ever before. They are commonly made from high-speed steel (HSS) or carbide, both renowned for their resilience and ability to maintain sharpness even after extended use They are commonly made from high-speed steel (HSS) or carbide, both renowned for their resilience and ability to maintain sharpness even after extended use

They are commonly made from high-speed steel (HSS) or carbide, both renowned for their resilience and ability to maintain sharpness even after extended use They are commonly made from high-speed steel (HSS) or carbide, both renowned for their resilience and ability to maintain sharpness even after extended use hex shank drill bit. In conclusion, the fiberglass rectangular tank is a testament to the fusion of advanced material science and practical engineering. Its robust construction, chemical resistance, customization options, and environmental sustainability make it a preferred choice for numerous industries. As technology continues to evolve, it is expected that the application and efficiency of these tanks will only improve, solidifying their position in the global market for storage solutions. Moreover, thread carbide extension rods offer excellent wear resistance From a sustainability standpoint, the S215 rock drill also stands out. Its efficient design reduces energy consumption, and its reliable performance cuts down on maintenance costs. These attributes contribute to lowering the environmental impact of mining operations by decreasing fuel usage and minimizing waste generation. Understanding and Utilizing theGRP Rectangular Tank An Efficient Storage Solution Fiberglass pipes are manufactured using a combination of glass fibers and a resin matrix, creating a composite material that boasts incredible resistance to corrosion, extreme temperatures, and high pressure. The 'high pressure' aspect refers to their ability to withstand pressures up to 4,000 psi or more, making them ideal for industries such as oil and gas, chemical processing, and water treatment.

hex shank drill bit. In conclusion, the fiberglass rectangular tank is a testament to the fusion of advanced material science and practical engineering. Its robust construction, chemical resistance, customization options, and environmental sustainability make it a preferred choice for numerous industries. As technology continues to evolve, it is expected that the application and efficiency of these tanks will only improve, solidifying their position in the global market for storage solutions. Moreover, thread carbide extension rods offer excellent wear resistance From a sustainability standpoint, the S215 rock drill also stands out. Its efficient design reduces energy consumption, and its reliable performance cuts down on maintenance costs. These attributes contribute to lowering the environmental impact of mining operations by decreasing fuel usage and minimizing waste generation. Understanding and Utilizing theGRP Rectangular Tank An Efficient Storage Solution Fiberglass pipes are manufactured using a combination of glass fibers and a resin matrix, creating a composite material that boasts incredible resistance to corrosion, extreme temperatures, and high pressure. The 'high pressure' aspect refers to their ability to withstand pressures up to 4,000 psi or more, making them ideal for industries such as oil and gas, chemical processing, and water treatment. In conclusion, mastery over the grp stack is a testament to a deep understanding of Unix-like systems. By adeptly managing the gids associated with processes, one can ensure that applications run with the necessary privileges without compromising system integrity. The grp stack is not just a technical feature; it is a fundamental pillar upholding the security and flexibility that define the Unix philosophy. Fiberglass tanks have become an increasingly popular choice in various industries due to their exceptional durability, corrosion resistance, and cost-effectiveness. These tanks, made from a composite material consisting of glass fibers embedded in a resin matrix, offer a wide range of advantages over traditional storage solutions. This article delves into the benefits and applications of fiberglass tanks that are currently available for sale.  rotary jackhammer. However, it requires a certain level of physical strength and expertise to handle, considering the considerable vibrations it generates. Safety precautions are paramount when using this tool, including wearing protective gear like earplugs, goggles, and steel-toed boots. Another notable feature is their durability. Fiberglass ducts are resistant to corrosion, unlike metal ducts that can rust over time. They also withstand extreme temperatures, making them suitable for both heating and cooling applications. Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance

rotary jackhammer. However, it requires a certain level of physical strength and expertise to handle, considering the considerable vibrations it generates. Safety precautions are paramount when using this tool, including wearing protective gear like earplugs, goggles, and steel-toed boots. Another notable feature is their durability. Fiberglass ducts are resistant to corrosion, unlike metal ducts that can rust over time. They also withstand extreme temperatures, making them suitable for both heating and cooling applications. Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance

Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance fiberglass duct. One of the main advantages of fiberglass scrubbers is their versatility. They can be used on a wide range of surfaces, from countertops to bathroom tiles to outdoor furniture. Their tough fibers are able to effectively remove dirt and grime without causing any damage to the surface being cleaned. The origins of the jackhammer can be traced back to the early 19th century, when it was first developed for use in mining operations. Its primary purpose was to break up hard rock and soil, allowing miners to extract valuable minerals more efficiently. Over time, the jackhammer has evolved significantly, with improvements in design and technology leading to increased power and versatility. In conclusion, high pressure fiberglass pipe represents a significant stride in engineering innovation. Its robustness, resilience, and adaptability make it an attractive choice for industries seeking efficient, cost-effective, and environmentally friendly piping solutions. As technology continues to advance, we can expect high pressure fiberglass pipe to play an even larger role in shaping the future of infrastructure and industrial processes.

fiberglass duct. One of the main advantages of fiberglass scrubbers is their versatility. They can be used on a wide range of surfaces, from countertops to bathroom tiles to outdoor furniture. Their tough fibers are able to effectively remove dirt and grime without causing any damage to the surface being cleaned. The origins of the jackhammer can be traced back to the early 19th century, when it was first developed for use in mining operations. Its primary purpose was to break up hard rock and soil, allowing miners to extract valuable minerals more efficiently. Over time, the jackhammer has evolved significantly, with improvements in design and technology leading to increased power and versatility. In conclusion, high pressure fiberglass pipe represents a significant stride in engineering innovation. Its robustness, resilience, and adaptability make it an attractive choice for industries seeking efficient, cost-effective, and environmentally friendly piping solutions. As technology continues to advance, we can expect high pressure fiberglass pipe to play an even larger role in shaping the future of infrastructure and industrial processes.

rotary jackhammer. However, it requires a certain level of physical strength and expertise to handle, considering the considerable vibrations it generates. Safety precautions are paramount when using this tool, including wearing protective gear like earplugs, goggles, and steel-toed boots. Another notable feature is their durability. Fiberglass ducts are resistant to corrosion, unlike metal ducts that can rust over time. They also withstand extreme temperatures, making them suitable for both heating and cooling applications. Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance

rotary jackhammer. However, it requires a certain level of physical strength and expertise to handle, considering the considerable vibrations it generates. Safety precautions are paramount when using this tool, including wearing protective gear like earplugs, goggles, and steel-toed boots. Another notable feature is their durability. Fiberglass ducts are resistant to corrosion, unlike metal ducts that can rust over time. They also withstand extreme temperatures, making them suitable for both heating and cooling applications. Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance

Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance fiberglass duct. One of the main advantages of fiberglass scrubbers is their versatility. They can be used on a wide range of surfaces, from countertops to bathroom tiles to outdoor furniture. Their tough fibers are able to effectively remove dirt and grime without causing any damage to the surface being cleaned. The origins of the jackhammer can be traced back to the early 19th century, when it was first developed for use in mining operations. Its primary purpose was to break up hard rock and soil, allowing miners to extract valuable minerals more efficiently. Over time, the jackhammer has evolved significantly, with improvements in design and technology leading to increased power and versatility. In conclusion, high pressure fiberglass pipe represents a significant stride in engineering innovation. Its robustness, resilience, and adaptability make it an attractive choice for industries seeking efficient, cost-effective, and environmentally friendly piping solutions. As technology continues to advance, we can expect high pressure fiberglass pipe to play an even larger role in shaping the future of infrastructure and industrial processes.

fiberglass duct. One of the main advantages of fiberglass scrubbers is their versatility. They can be used on a wide range of surfaces, from countertops to bathroom tiles to outdoor furniture. Their tough fibers are able to effectively remove dirt and grime without causing any damage to the surface being cleaned. The origins of the jackhammer can be traced back to the early 19th century, when it was first developed for use in mining operations. Its primary purpose was to break up hard rock and soil, allowing miners to extract valuable minerals more efficiently. Over time, the jackhammer has evolved significantly, with improvements in design and technology leading to increased power and versatility. In conclusion, high pressure fiberglass pipe represents a significant stride in engineering innovation. Its robustness, resilience, and adaptability make it an attractive choice for industries seeking efficient, cost-effective, and environmentally friendly piping solutions. As technology continues to advance, we can expect high pressure fiberglass pipe to play an even larger role in shaping the future of infrastructure and industrial processes.